Stainless steel is a kind of high alloy steel that can resist corrosion in the air or chemical corrosive media. The reason why stainless steel can resist corrosion is mainly due to the magical effect of metallic chromium in its composition. On the one hand, a very thin chromium film is formed on the surface of the steel to isolate the oxygen that has penetrated into the steel from the steel; on the other hand, the addition of chromium increases the potential of the iron-based solid solution electrode.

"Stainless steel" is just a general term, which can mean more than one hundred industrial stainless steels. Usually according to the structure can be divided into austenitic stainless steel (mainly Cr18-Ni18 series and its derivatives), ferritic stainless steel, martensitic stainless steel (mainly Cr13 series), duplex stainless steel and precipitation hardening stainless steel.

The development and progress of my country's stainless steel industry is relatively late, but with the rapid development of the national economy, the people's living standards have improved significantly, which has stimulated the demand for stainless steel. Stainless steel is the most widely used steel surface treatment method with the best performance-to-price ratio in the world today. After entering the 1990s, my country's stainless steel industry has entered a period of rapid development, and the growth rate of stainless steel demand is much higher than the global level. A large number of excellent domestic stainless steel brands have risen rapidly and have gradually become leaders in the stainless steel industry!

Stainless steel is usually divided into:

1. Ferritic stainless steel. Containing 12% to 30% chromium. Its corrosion resistance, toughness and weldability increase with the increase of chromium content, and its resistance to chloride stress corrosion is better than other types of stainless steel.

2. Austenitic stainless steel. The chromium content is more than 18%, and it also contains about 8% nickel and a small amount of molybdenum, titanium, nitrogen and other elements. Good overall performance, resistant to corrosion by various media.

3. Austenitic-ferritic duplex stainless steel. It has the advantages of austenitic and ferritic stainless steel, and has superplasticity.

4. Martensitic stainless steel. High strength, but poor plasticity and weldability.

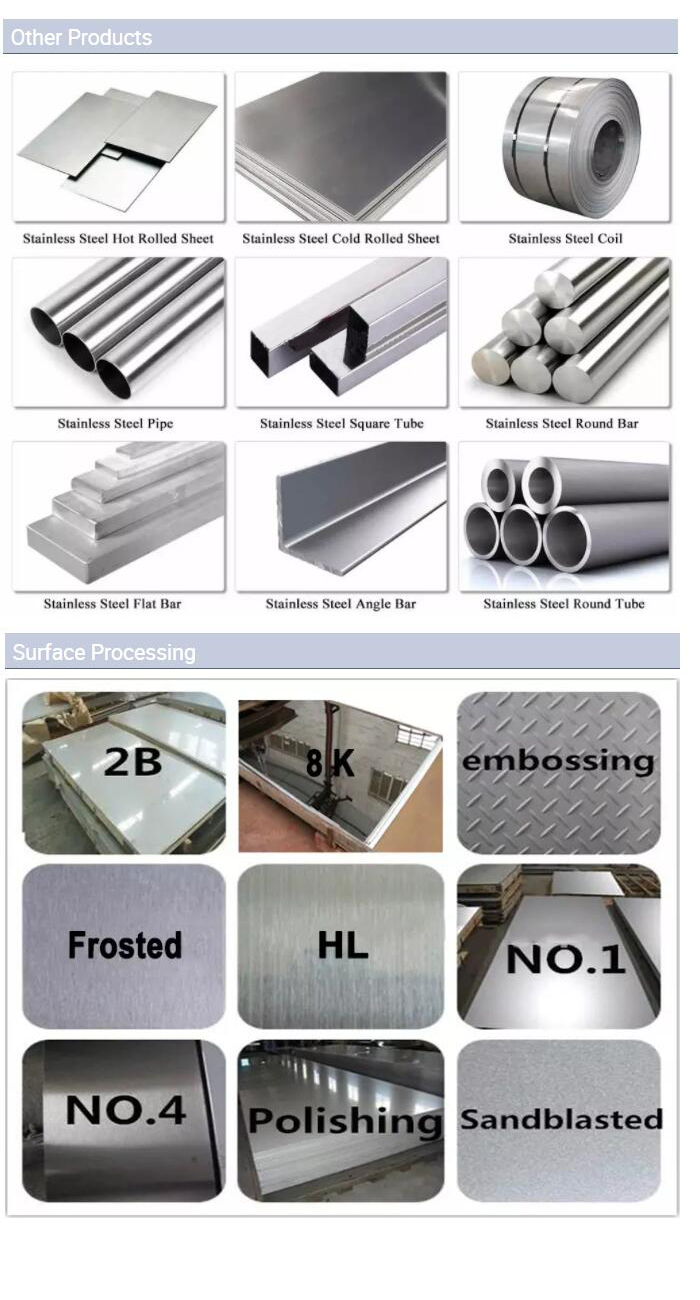

Specifications and dimensions of stainless steel:

Stainless steel plates include coils and original flat coils.

1. Coils are divided into cold rolled coils and hot rolled coils, trimmed coils and unedged coils

2. The thickness of cold-rolled coils is generally 0.3-3.0mm, and cold-rolled plates with thicknesses of 4.0-6.0mm are also available. The widths are 1000mm, 1219mm, and 1500mm, expressed by 2B.

3. The thickness of hot-rolled coils is generally 3.0-14.0mm, and there are also 16.0mm coils, with widths of 1250mm, 1500mm, 1800mm, and 2000mm, denoted by NO.1.

4. Rolls with widths of 1500mm, 1800m, and 2000mm are trimmed rolls

5. The width of the burr roll is generally 1520, 1530, 1550, 2200, etc. wider than the normal width. In terms of price, there is a price difference between trimmed rolls and raw-edged rolls of the same model.

6. The roll can be opened according to the length required by the customer. After being flattened by a flattening machine, it is called a flat plate. Cold rolling generally opens 1m*2m, 1219*2438 is also called 4*8 feet, and hot rolling generally opens 1.5m*6m, 1.8m*6m, 2m*6m, and those opened according to these dimensions are called standard plates or fixed-length plates.

The original plate is also called single sheet rolling:

1. The thickness of the original plate is generally between 4mm-80mm, and there are also 100mm and 120mm. This thickness can be customized.

2. The width is 1.5m, 1.8m, 2m, and the length is more than 6 meters.

3. Features: The original plate is large in size, high in cost, difficult to pickle, and not easy to transport.

Thickness distinction:

1. During the rolling process of the steel mill machinery, the rollers are heated and slightly deformed, resulting in deviations in the thickness of the rolled plates, generally the middle is thick and the two sides are thin. When measuring the thickness of the board, the state stipulates that the middle part of the board should be measured.

2. The reason for the tolerance is that according to the market and customer needs, it is generally divided into large tolerance and small tolerance: for example.

The proportion of each material of stainless steel:

1, 304, 304L, 304J1, 321, 201, 202 specific gravity 7.93

2. The proportion of 316, 316L, 309S, 310S is 7.98

3. The proportion of 400 series is 7.75

Learn More :

In order to offer you the exact quotaiton, could you pls kindly inform us the detailed item, size, material grade, quantity and other requirements.